Insulating Machinery

Discover how insulating machinery can reduce noise pollution, boost productivity, and create a healthier workplace environment.

In today’s fast-paced industrial landscape, noise pollution has become an increasingly prevalent issue, impacting not only workplace productivity but also employee well-being. The clamor from machinery can lead to distractions, stress, and long-term hearing damage, making it essential for businesses to address the sound levels produced by their operations.

Insulating machinery to reduce noise is a practical solution that not only creates a quieter work environment but also promotes a culture of health and safety. This introduction aims to explore effective strategies for implementing noise reduction techniques, the benefits of a quieter workplace, and the technologies available to help businesses achieve significant reductions in noise pollution.

Introduction to Noise Pollution in the Workplace

In today’s fast-paced work environments, noise pollution has become an increasing concern. The constant hum of machinery, the clatter of tools, and even the persistent chatter in open office spaces contribute to a cacophony that can be both distracting and harmful to one’s health. For workers, this constant noise can lead to stress, reduced productivity, and even long-term hearing loss.

Understanding Noise Pollution’s Impact

Noise pollution isn’t just an annoyance; it’s a health hazard. Continuous exposure to loud environments can lead to hearing impairment, increased stress levels, and other serious health issues. For businesses, this means a potential increase in sick leaves, decreased efficiency, and lower morale among employees. Recognizing the impact of noise pollution is the first step towards creating a healthier work environment.

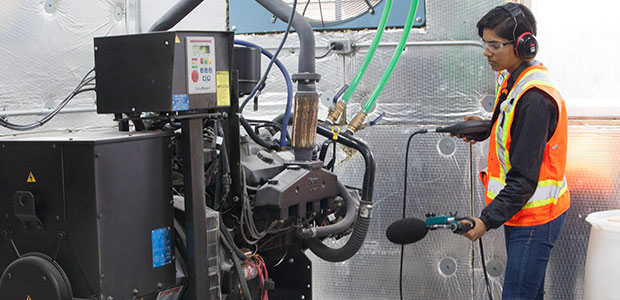

The Role of Insulation in Noise Reduction

One effective method to combat noise pollution is through insulating machinery. By reducing the noise emitted by equipment, businesses can create a more conducive work environment. Noise barriers and soundproofing techniques not only protect the hearing of employees but also enhance focus and overall workplace satisfaction.

Techniques for Insulating Machinery

When it comes to reducing machinery noise, several insulation techniques can be implemented. Each method offers unique benefits, and the choice depends on the specific needs of the workplace.

Using Acoustic Panels

Acoustic panels are a popular choice for soundproofing. These panels are designed to absorb sound waves, reducing noise levels significantly. Installed around noisy machinery or on walls, they effectively diminish the reverberation and echo, providing a quieter workspace.

Encasing Equipment with Insulation

Another effective method involves encasing machinery with specialized insulation materials. This technique creates a barrier that absorbs and dampens sound, preventing it from spreading throughout the workplace. It’s particularly useful in industries where large machines operate continuously.

Implementing Vibration Isolation

Vibration is a major contributor to noise pollution in industrial settings. By using vibration isolators, which are specially designed mounts or pads, machinery vibrations can be minimized. This not only reduces noise but also prolongs the life of the equipment by reducing wear and tear.

Benefits of a Noise-Reduced Workplace

A quieter workplace brings a host of advantages, from improved health to enhanced productivity.

Healthier Employees and Reduced Stress

Reducing noise pollution directly impacts the health of employees. With less noise, workers experience lower stress levels, improved concentration, and reduced risk of hearing damage. This leads to a happier and more engaged workforce.

Boosted Productivity and Focus

A quieter environment naturally leads to better focus. Employees can concentrate on their tasks without the constant background noise, resulting in higher productivity and better quality of work.

Long-term Cost Savings

While the initial investment in insulation might seem high, the long-term savings are substantial. Healthier employees mean fewer sick leaves and reduced healthcare costs, while improved productivity directly impacts the company’s bottom line.

Real-world Examples of Noise Reduction

Several companies have successfully implemented noise reduction strategies to create better workplaces.

Industrial Giants Making a Difference

Industrial construction companies in Colorado have been at the forefront of noise reduction. By incorporating advanced insulation techniques, they’ve managed to create safer and more efficient work environments.

Office Spaces Opting for Acoustic Solutions

Beyond factories, office spaces are also recognizing the benefits of noise reduction. Many have started installing acoustic panels and using furniture designed to dampen sound, creating more peaceful and productive environments.

The Positive Ripple Effect

When companies invest in reducing noise pollution, the benefits extend beyond the workplace. Clients and partners notice the commitment to employee well-being, enhancing the company’s reputation and potentially leading to new business opportunities.

Conclusion

Reducing noise pollution in the workplace is not just a luxury; it’s a necessity for modern businesses. By investing in insulation and noise reduction techniques, companies can create healthier, more productive environments for their employees. This proactive approach not only boosts morale and efficiency but also safeguards the long-term health of the workforce, ensuring a win-win for everyone involved.

Ensure your workplace is a haven of productivity and well-being by considering noise insulation solutions today. Whether you’re in a bustling office or a noisy factory, the benefits of a quieter work environment are clear.